|

|

Q.

Is the check result normal?

|

|

|

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions  ). ).

|

|

|

|

|

|

Q.

Is the check result normal?

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

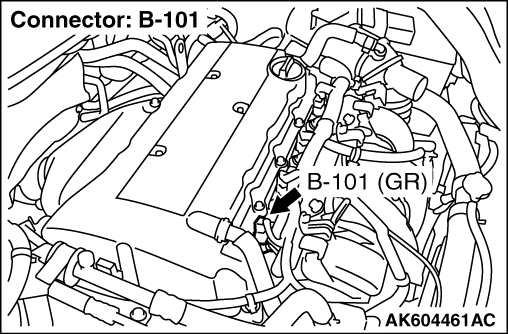

- Check No. 1 injector itself (Refer to

). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the No. 1 injector. Replace the No. 1 injector.

|

|

|

|

|

|

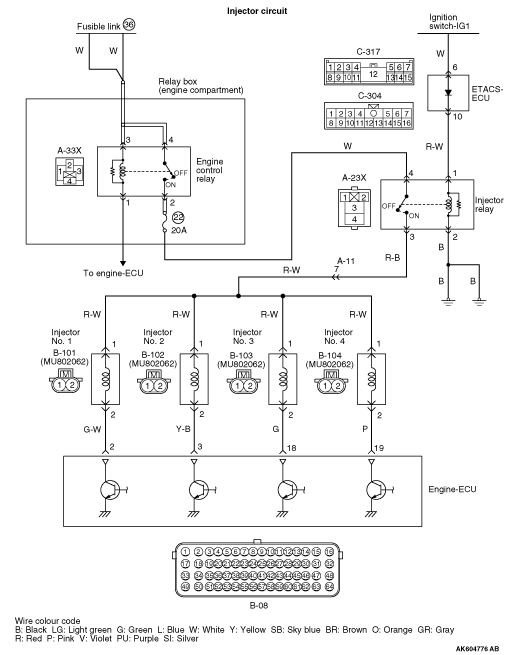

- Disconnect connector, and measure at harness side.

- Ignition switch: ON

- Voltage between terminal No. 1 and earth.

|

|

|

Q.

Is the check result normal?

|

|

|

Q.

Is the check result normal?

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

- Check injector relay itself (Refer to

). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the injector relay. Replace the injector relay.

|

|

|

|

|

|

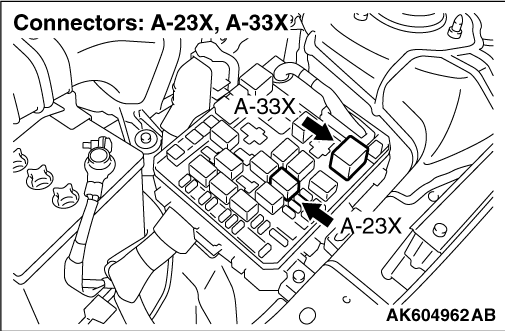

- Remove relay and measure at connector side.

- Resistance between terminal No. 2 and earth.

|

|

|

OK: Continuity (2 Ω

or less)

|

|

|

Q.

Is the check result normal?

|

|

|

Check and repair harness between A-23X (terminal No.

2) injector relay connector and body earth.

- Check earthing line for open circuit and damage.

|

|

|

|

|

|

- Remove relay and measure at connector side.

- Ignition switch: ON

- Resistance between terminal No. 1 and earth.

|

|

|

Q.

Is the check result normal?

|

|

|

Q.

Is the check result normal?

|

|

|

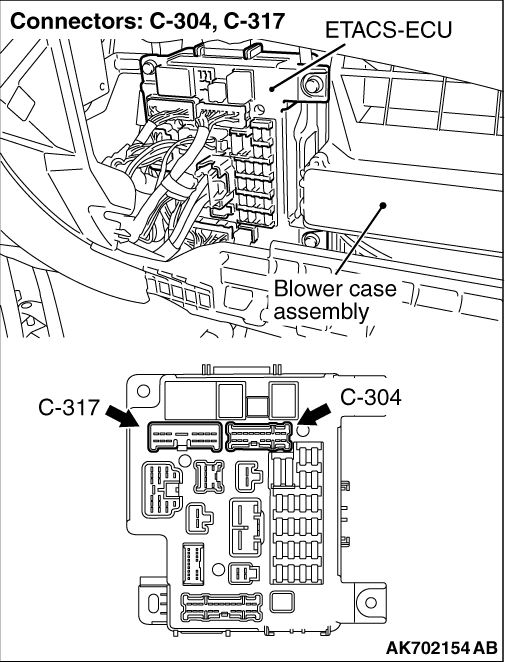

Check and repair harness between C-304 (terminal No.

10) ETACS-ECU connector and A-23X (terminal No. 1) injector relay connector.

- Check power supply line for open/short circuit.

|

|

|

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

- Remove relay and measure at connector side.

- Ignition switch: ON

- Voltage between terminal No. 4 and earth.

|

|

|

Q.

Is the check result normal?

|

|

|

Q.

Is the check result normal?

|

|

|

Check and repair harness between A-33X (terminal No.

2) engine control relay connector and A-23X (terminal No. 4) injector relay connector.

- Check power supply line for open/short circuit.

|

|

|

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

- Check power supply line for open/short circuit.

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

|

|

|

|

Q.

Is the check result normal?

|

|

|

Check and repair harness between C-304 (terminal No.

10) ETACS-ECU connector and A-23X (terminal No. 1) injector relay connector.

- Check power supply line for damage.

|

|

|

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

Q.

Are the check results normal?

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

- Check power supply line for damage.

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

|

|

|

|

- Check power supply line for damage.

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

|

|

|

|

Q.

Is the check result normal?

|

|

|

Repair or replace the connector. Repair or replace the connector.

|

|

|

|

|

|

- Check output line for open/short circuit and damage.

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the damaged harness wire. Repair the damaged harness wire.

|

|

|

|

|

|

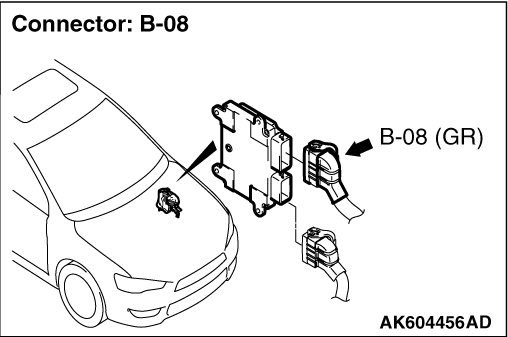

- Disconnect engine-ECU connector, and connect special tool power plant ECU

check harness (MB992110) to measure at connector for inspection.

- Engine: Idling

- Transmission: Neutral <M/T> or P range <CVT>

- Voltage between terminal No. 2 and earth.

|

|

|

OK: Waveforms should be displayed on inspection procedure using an oscilloscope

(Refer to  ). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions  ). ).

|

|

|

|

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions  ).

).

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions  ).

). Go to Step 2 .

Go to Step 2 . Go to Step 3 .

Go to Step 3 . Repair or replace the connector.

Repair or replace the connector. Go to Step 4 .

Go to Step 4 . Replace the No. 1 injector.

Replace the No. 1 injector. Go to Step 14 .

Go to Step 14 . Go to Step 5 .

Go to Step 5 . Go to Step 6 .

Go to Step 6 . Repair or replace the connector.

Repair or replace the connector. Go to Step 7 .

Go to Step 7 . Replace the injector relay.

Replace the injector relay. Go to Step 8 .

Go to Step 8 .

Go to Step 10 .

Go to Step 10 . Go to Step 9 .

Go to Step 9 .

Repair or replace the connector.

Repair or replace the connector. Go to Step 12 .

Go to Step 12 . Go to Step 11 .

Go to Step 11 .

Repair or replace the connector.

Repair or replace the connector. Go to Step 13 .

Go to Step 13 . Repair the damaged harness wire.

Repair the damaged harness wire.

Repair or replace the connector.

Repair or replace the connector. Go to Step 15 .

Go to Step 15 . Repair or replace the connector.

Repair or replace the connector. Go to Step 16 .

Go to Step 16 . Repair the damaged harness wire.

Repair the damaged harness wire. Go to Step 17 .

Go to Step 17 . Repair the damaged harness wire.

Repair the damaged harness wire. Go to Step 18 .

Go to Step 18 . Repair or replace the connector.

Repair or replace the connector. Go to Step 19 .

Go to Step 19 . Repair the damaged harness wire.

Repair the damaged harness wire. ).

). Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/Inspection

Service Points -

How to Cope with Intermittent Malfunctions  ).

). Replace the engine-ECU.

Replace the engine-ECU.