Code No.C1000

Abnormality in stop lamp switch circuit

|

|

| caution |

- If there is

any problem in the CAN bus lines, an incorrect diagnosis code may be set. Prior to this diagnosis,

diagnose the CAN bus lines (Refer to GROUP 54C, Trouble code diagnosis

). ).

- Whenever ECU is replaced, ensure that the CAN bus lines are normal.

- When the hydraulic unit (integrated with ASC-ECU) is replaced, always carry out

the calibration of the steering wheel sensor, the G and yaw rate sensor and brake fluid pressure

sensor (Refer to

, ,  and and  ). ).

|

|

|

|

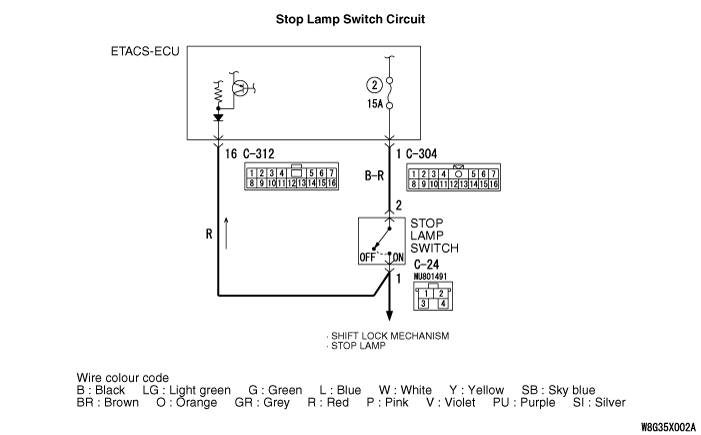

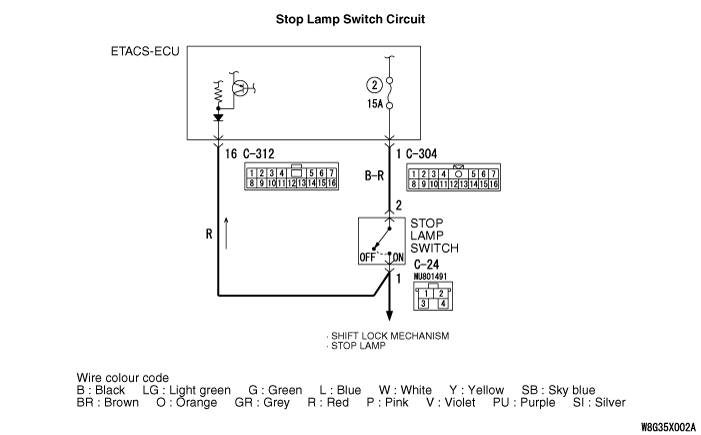

ETACS-ECU sends the ON signal generated when the brake pedal is depressed and OFF signal

generated when it is released to ASC-ECU via the CAN bus lines.

|

|

|

DIAGNOSIS CODE SET CONDITIONS

|

|

|

This diagnosis code is set in the following case.

|

|

|

- When the vehicle has run for a long time with the stop lamp switch turned

ON.

- When the OFF status of the stop lamp switch does not match the vehicle attitude

|

|

|

- Improper adjustment of stop lamp switch installation position

- Stop lamp switch malfunction

- Malfunction of the stop lamp switch

- Damaged wiring harness and connectors

- Malfunction of ETACS-ECU

- ASC-ECU malfunction

|

|

|

STEP 1. M.U.T.-III CAN bus diagnosis

|

|

|

Use M.U.T.-III to diagnose the CAN bus lines.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table  ).

On completion, go to Step 2. ).

On completion, go to Step 2.

|

|

|

|

|

|

STEP 2. Diagnosis code recheck after resetting CAN bus lines

|

|

|

Q.

Is the diagnosis code No.C1000 set?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

This diagnosis is complete. This diagnosis is complete.

|

|

|

|

|

|

STEP 3. Stop lamp operation check

|

|

|

(1)Turn the ignition switch to the ON position.

|

|

|

(2)Check the stop lamp operation when the brake pedal is depressed. Check that the

stop lamp illuminates when the brake pedal is depressed and that it goes out when the brake

pedal is released.

OK:

When the brake pedal is released: OFF

When the brake pedal is depressed: ON

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 11. Go to Step 11.

|

|

|

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

STEP 4. Check for stop lamp switch installation

|

|

|

Refer to GROUP 35A - On-vehicle Service  . .

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

Install the stop lamp switch correctly (Refer to GROUP 35A - On-vehicle

Service Install the stop lamp switch correctly (Refer to GROUP 35A - On-vehicle

Service  ), and then go to Step 14. ), and then go to Step 14.

|

|

|

|

|

|

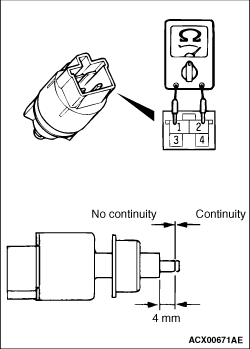

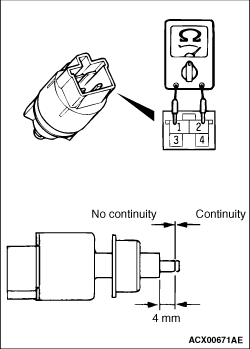

STEP 5. Stop lamp switch continuity check

|

|

|

(1)Remove the stop lamp switch (Refer to GROUP 35A -Brake Pedal  ). ).

|

|

(2)Connect the circuit tester (Ω range) to the stop lamp switch connector terminals

No.1 and 2.

(3)When no continuity is detected with the plunger pressed from the edge of the outer

case by the dimension shown in the figure and when continuity is detected with the plunger released,

the stop lamp switch is in good condition.

Q.

Is the check result normal?

Go to Step 6. Go to Step 6.

Replace the stop lamp switch and then go to Step 14. Replace the stop lamp switch and then go to Step 14.

|

|

|

STEP 6. Check any other diagnosis code is set.

|

|

|

Check if stop lamp-related diagnosis code is set (Refer to GROUP 54A - Rear Combination

Lamp  ). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 7. Go to Step 7.

|

|

|

|

|

|

Diagnose the rear combination lamp (Refer to GROUP 54A, Rear Combination Lamp - Diagnosis

Code Chart Diagnose the rear combination lamp (Refer to GROUP 54A, Rear Combination Lamp - Diagnosis

Code Chart  ). Then go to Step 14. ). Then go to Step 14.

|

|

|

|

|

|

Refer to GROUP 54A - Battery Test  . .

|

|

|

Q.

Is the battery in good condition?

|

|

|

Go to Step 8. Go to Step 8.

|

|

|

|

|

|

Replace the battery, and go to Step 8. Replace the battery, and go to Step 8.

|

|

|

|

|

|

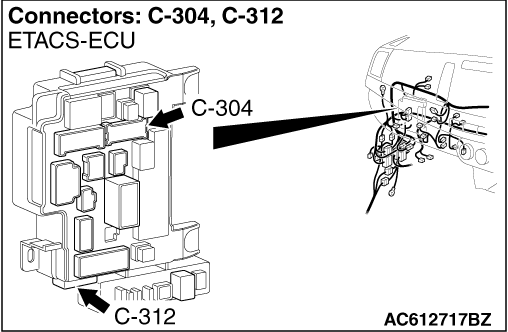

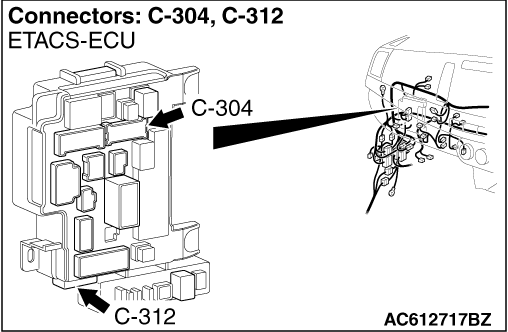

STEP 8. Voltage measurement at C-304 ETACS-ECU connector

|

|

|

(1)Turn the ignition switch to the ON position.

|

|

|

(2)Measure the voltage between the terminal No.1 and the body earth.

OK: Approximately battery voltage

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

Go to Step 10. Go to Step 10.

|

|

|

|

|

|

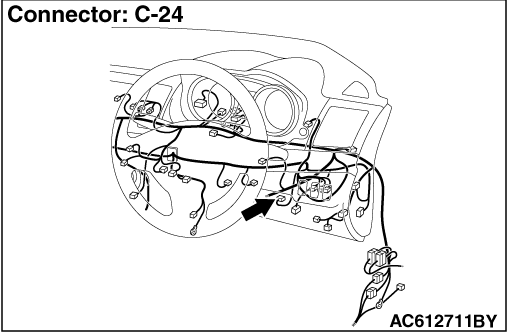

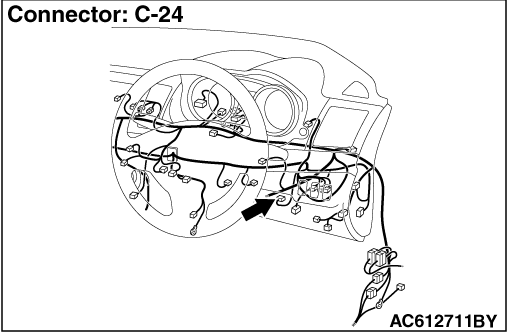

STEP 9. Connector check: C-304 ETACS-ECU connector, C-24 stop lamp

switch connector

|

|

|

Q.

Is the check result normal?

|

|

|

The short or open circuit between the C-304 ETACS-ECU connector terminal No.1

and the C-24 stop lamp switch connector terminal No.2 may be present. Repair the wiring harness

between the C-304 ETACS-ECU connector terminal No.1 and the C-24 stop lamp switch connector

terminal No.2. The short or open circuit between the C-304 ETACS-ECU connector terminal No.1

and the C-24 stop lamp switch connector terminal No.2 may be present. Repair the wiring harness

between the C-304 ETACS-ECU connector terminal No.1 and the C-24 stop lamp switch connector

terminal No.2.

|

|

|

|

|

|

Repair the defective connector. Repair the defective connector.

|

|

|

|

|

|

STEP 10. ETACS-ECU fuse No.2 check

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ),

and then go to Step 13. ),

and then go to Step 13.

|

|

|

|

|

|

Replace fuse No.2. Then go to Step 14. Replace fuse No.2. Then go to Step 14.

|

|

|

|

|

|

STEP 11. Voltage measurement at C-312 ETACS-ECU connector

|

|

|

(1)Disconnect C-312 ETACS-ECU connector, and measure the voltage at ETACS-ECU side.

|

|

|

(2)Turn the ignition switch to the ON position.

|

|

|

(3)

| caution |

Do not depress the brake pedal.

|

Measure the voltage between the terminal No.16 and the body earth.

OK: Approximately 5 V

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 12. Go to Step 12.

|

|

|

|

|

|

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ),

and then go to Step 14. ),

and then go to Step 14.

|

|

|

|

|

|

STEP 12. Connector check: C-312 ETACS-ECU connector, C-24 stop lamp

switch connector

|

|

|

Q.

Is the check result normal?

|

|

|

The short circuit between the C-312 ETACS-ECU connector terminal No.16 and the

C-24 stop lamp switch connector terminal No.1 may be present. Repair the wiring harness between

the C-312 ETACS-ECU connector terminal No.16 and the C-24 stop lamp switch connector terminal

No.1. The short circuit between the C-312 ETACS-ECU connector terminal No.16 and the

C-24 stop lamp switch connector terminal No.1 may be present. Repair the wiring harness between

the C-312 ETACS-ECU connector terminal No.16 and the C-24 stop lamp switch connector terminal

No.1.

|

|

|

|

|

|

Repair the defective connector. Repair the defective connector.

|

|

|

|

|

|

STEP 13. Check whether the diagnosis code is reset.

|

|

|

Q.

Is the diagnosis code No.1000 set?

|

|

|

Replace the ASC-ECU (Refer to Replace the ASC-ECU (Refer to  ). Then go to

Step 14. ). Then go to

Step 14.

|

|

|

|

|

|

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction  ). ).

|

|

|

|

|

|

STEP 14. Check whether the diagnosis code is reset.

|

|

|

Q.

Is diagnosis code No.1000 set?

|

|

|

Return to Step 1. Return to Step 1.

|

|

|

|

|

|

This diagnosis is complete. This diagnosis is complete.

|

|

|

|

Go to Step 3.

Go to Step 3. Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnosis table  ).

On completion, go to Step 2.

).

On completion, go to Step 2. Go to Step 3.

Go to Step 3. This diagnosis is complete.

This diagnosis is complete. Go to Step 11.

Go to Step 11. Go to Step 4.

Go to Step 4. .

. Go to Step 5.

Go to Step 5. Install the stop lamp switch correctly (Refer to GROUP 35A - On-vehicle

Service

Install the stop lamp switch correctly (Refer to GROUP 35A - On-vehicle

Service  ), and then go to Step 14.

), and then go to Step 14. ).

).

Go to Step 6.

Go to Step 6. Replace the stop lamp switch and then go to Step 14.

Replace the stop lamp switch and then go to Step 14. ).

). Go to Step 7.

Go to Step 7. Diagnose the rear combination lamp (Refer to GROUP 54A, Rear Combination Lamp - Diagnosis

Code Chart

Diagnose the rear combination lamp (Refer to GROUP 54A, Rear Combination Lamp - Diagnosis

Code Chart  ). Then go to Step 14.

). Then go to Step 14. .

. Go to Step 8.

Go to Step 8. Replace the battery, and go to Step 8.

Replace the battery, and go to Step 8. Go to Step 9.

Go to Step 9. Go to Step 10.

Go to Step 10. The short or open circuit between the C-304 ETACS-ECU connector terminal No.1

and the C-24 stop lamp switch connector terminal No.2 may be present. Repair the wiring harness

between the C-304 ETACS-ECU connector terminal No.1 and the C-24 stop lamp switch connector

terminal No.2.

The short or open circuit between the C-304 ETACS-ECU connector terminal No.1

and the C-24 stop lamp switch connector terminal No.2 may be present. Repair the wiring harness

between the C-304 ETACS-ECU connector terminal No.1 and the C-24 stop lamp switch connector

terminal No.2. Repair the defective connector.

Repair the defective connector. Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ),

and then go to Step 13.

),

and then go to Step 13. Replace fuse No.2. Then go to Step 14.

Replace fuse No.2. Then go to Step 14. Go to Step 12.

Go to Step 12. Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ),

and then go to Step 14.

),

and then go to Step 14. The short circuit between the C-312 ETACS-ECU connector terminal No.16 and the

C-24 stop lamp switch connector terminal No.1 may be present. Repair the wiring harness between

the C-312 ETACS-ECU connector terminal No.16 and the C-24 stop lamp switch connector terminal

No.1.

The short circuit between the C-312 ETACS-ECU connector terminal No.16 and the

C-24 stop lamp switch connector terminal No.1 may be present. Repair the wiring harness between

the C-312 ETACS-ECU connector terminal No.16 and the C-24 stop lamp switch connector terminal

No.1. Repair the defective connector.

Repair the defective connector. Replace the ASC-ECU (Refer to

Replace the ASC-ECU (Refer to  ). Then go to

Step 14.

). Then go to

Step 14. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction  ).

). Return to Step 1.

Return to Step 1. This diagnosis is complete.

This diagnosis is complete.