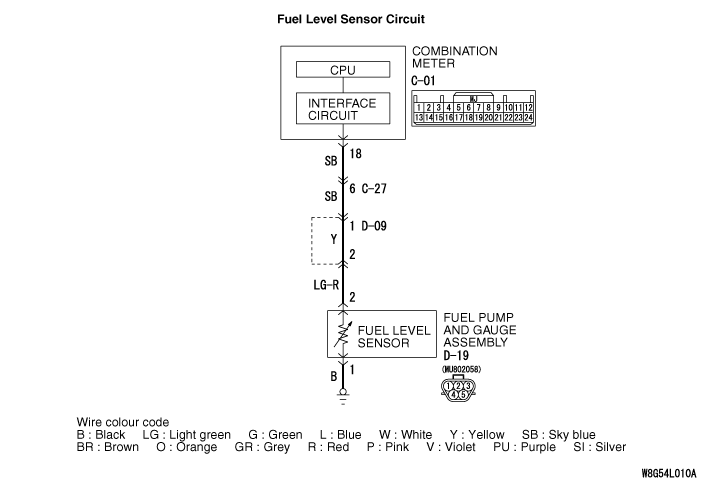

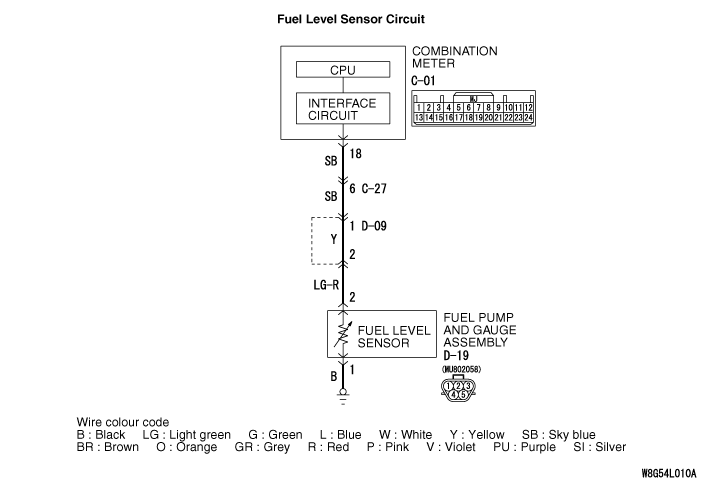

Code No.B1201: Fuel information error

| caution |

Whenever the ECU is replaced, ensure that the communication circuit is normal.

|

TROUBLE JUDGMENT

With the ignition switch at the ON position and the system voltage at 10 -16 V (data from ETACS-ECU), if the combination meter detects the abnormal resistance of fuel level sensor circuit for 64 seconds continuously, the diagnosis code No. B1201 is stored.

PROBABLE CAUSES

- Damaged harness wires and connectors

- Malfunction of fuel pump and gauge assembly

- Malfunction of combination meter

|

|

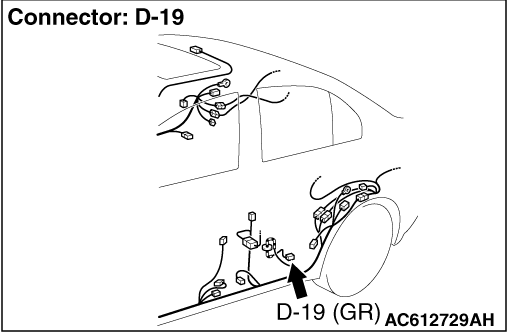

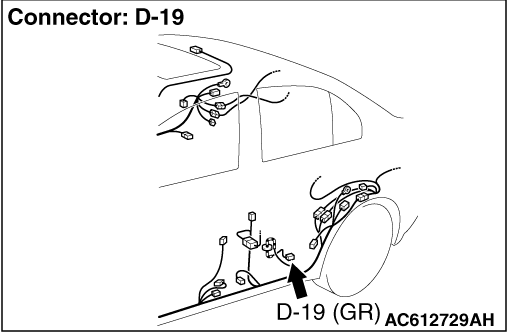

STEP 1. Connector check: D-19 fuel pump and gauge assembly connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 2. Go to Step 2.

|

|

|

|

|

|

Repair the connector, and then go to Step 9. Repair the connector, and then go to Step 9.

|

|

|

|

|

|

STEP 2. Fuel pump and gauge assembly check

|

|

|

Check the fuel pump and gauge assembly. Refer to  . .

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Replace the fuel pump and gauge assembly. Replace the fuel pump and gauge assembly.

|

|

|

|

|

|

STEP 3. Check of fuel gauge (main) circuit

|

|

|

(1)Disconnect the D-19 fuel pump and gauge assembly connector.

|

|

|

(2)Use the special tool Check harness (MB991219) to connect a test lamp (12 V - 3.4 W) between the wiring harness connector terminals 1 and 2.

|

|

|

(3)Turn the ignition switch to the ON position.

|

|

|

(4)Check if the test lamp illuminates.

OK: Illuminates

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 8. Go to Step 8.

|

|

|

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

STEP 4. Resistance measurement at the D-19 fuel pump and gauge assembly connector

|

|

|

(1)Disconnect the fuel pump and gauge unit (main) connector, the measure at the harness side.

|

|

|

(2)Measure the resistance between the D-19 fuel pump and gauge assembly connector terminal No. 1 and the body earth.

OK: Continuity exists (2 Ω or less)

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 6. Go to Step 6.

|

|

|

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

STEP 5. Check the wiring harness between the D-19 fuel pump and gauge assembly connector terminal No. 1 and the body earth.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

Repair the wiring harness, and then go to Step 9. Repair the wiring harness, and then go to Step 9.

|

|

|

|

|

|

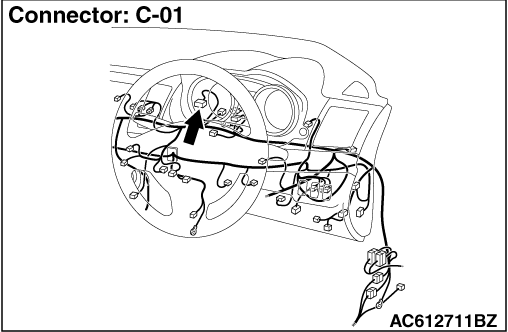

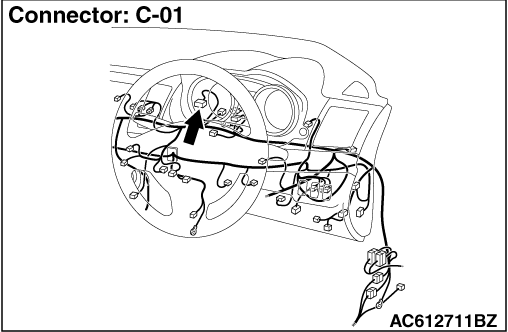

STEP 6. Connector check: C-01 combination meter connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 7. Go to Step 7.

|

|

|

|

|

|

Repair the connector, and then go to Step 9. Repair the connector, and then go to Step 9.

|

|

|

|

|

|

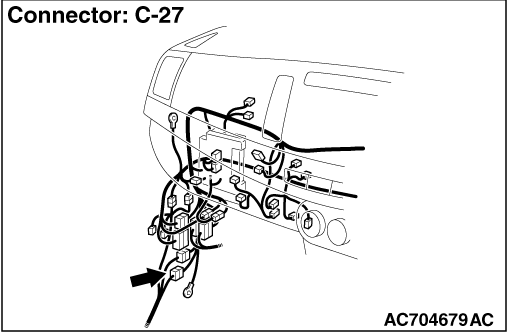

STEP 7. Check the wiring harness between the C-01 combination meter connector terminal No. 18 and the D-19 fuel pump and gauge assembly connector terminal No. 2

|

|

|

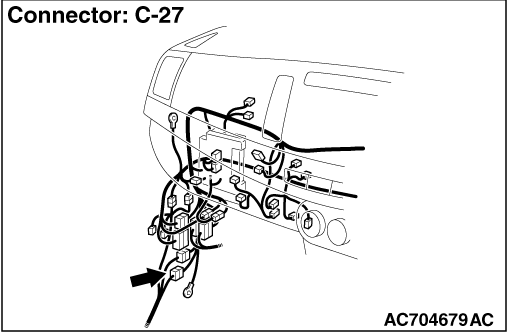

| note |

Before the wiring harness check, check the intermediate connectors C-27 and D-09, and repair them if necessary.

|

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 8. Go to Step 8.

|

|

|

|

|

|

Repair the wiring harness, and then go to Step 9. Repair the wiring harness, and then go to Step 9.

|

|

|

|

|

|

STEP 8. M.U.T.-III actuator test

|

|

|

- Item 03: Fuel gauge (target value): 0 →100%

|

|

|

OK: The fuel gauge operates.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

Replace the combination meter Replace the combination meter

|

|

|

|

|

|

STEP 9. Check whether the diagnosis code is reset.

|

|

|

Check again if the diagnosis code is set to the combination meter.

|

|

|

(1)Erase the diagnosis code.

|

|

|

(2)Turn the ignition switch from "LOCK" (OFF) position to "ON" position.

|

|

|

(3)Check if diagnosis code is set.

|

|

|

Q.

Is the diagnosis code set?

|

|

|

Replace the combination meter Replace the combination meter

|

|

|

|

|

|

The diagnosis is complete. The diagnosis is complete.

|

|

|

|

Go to Step 2.

Go to Step 2.

Go to Step 2.

Go to Step 2. Repair the connector, and then go to Step 9.

Repair the connector, and then go to Step 9. .

. Go to Step 3.

Go to Step 3. Replace the fuel pump and gauge assembly.

Replace the fuel pump and gauge assembly. Go to Step 8.

Go to Step 8. Go to Step 4.

Go to Step 4. Go to Step 6.

Go to Step 6. Go to Step 5.

Go to Step 5. Go to Step 9.

Go to Step 9. Repair the wiring harness, and then go to Step 9.

Repair the wiring harness, and then go to Step 9. Go to Step 7.

Go to Step 7. Repair the connector, and then go to Step 9.

Repair the connector, and then go to Step 9. Go to Step 8.

Go to Step 8. Repair the wiring harness, and then go to Step 9.

Repair the wiring harness, and then go to Step 9. Go to Step 9.

Go to Step 9. Replace the combination meter

Replace the combination meter Replace the combination meter

Replace the combination meter The diagnosis is complete.

The diagnosis is complete.